Last Thursday, October 7th 2010 the CAWP hosted an open house day. The CutMyTimber Founders Greg Howes and Stefan Schneider were present for this important and very interesting event.

The Hundegger Canada Crew: Markus Schellenberg with his very nice wife

and of course the machine doesn't run without a tech team. These Europeans always smile if there is a beer mug around. This one is made of Fir and milled on the 5-axis K2 joinery machine (in the background):

Hundegger ran some demos on their K2-5 axis machine. The type of machine that CutMyTimber is using for most of their complex projects:

But as impressive as the K2 is the real big news was the presentation of their soon to be released (in Europe first) 6 axis K2-Robot with fully automatic tool changer:

Of course the machine doesn't run without software. Cadwork was present as well:

Software and machine are capable to mill about any shape and angle. Bellow a few samples:

The event also featured multiple speakers from different organizations and companies:

A great occasion for CutMyTimber C.E.O Stefan Schneider to talk about Digital manufacturing and the future of building:

Main part of the speech was the difference between BIM and FIM and why it is critical to use accurate Fabrication Information Models in order to produce today's buildings and building components:

The 2nd part of the presentation was about the transfer from architectural data into a 3D FIM model, process definition, export to CAM software and various processing methods for steel and timber parts as well as prefab wall panels:

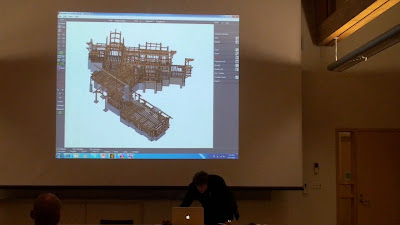

Accurate and very detailed Cadwork 3D FIM model

Cadwork to Hundegger K2 CNC interface and Hundegger EKP single part CAM system

Finshed scarf joint detail cut by Hundegger K2 joinery machine

Same process for steel I-beams and steel plates. Stefan shows a video of a Steel I-beam processor in action.

And of course in the end a short outlook about the future of building. This is what CutMyTimber is all about:

....of course that leads to surprised faces and great discussions:

a big THANK YOU to the UBC CAWP team for organizing a great event!!!

No comments:

Post a Comment