Last week we completed fabrication of a panelized passive house in Portland. Trucks continue to be loaded and assembly will begin next week. We are really excited about this project and how it will demonstrate advanced digital fabrication and high-performance.

We have great partners on this project and are very excited to be working with Guido Wimmers PhD, our passive house trainer, staff member of the Canadian Passive House Institute, advisor to the City of Vancouver on the passive house design toolkits, and owner of building evolution.

We are working with an incredible client, Shirra, who is great to work with and who is very interested in demonstrating the benefits of passive house on her own residence. We are also excited to be working with our builder friends at the Econ Group, Marcel Studer and Michael Dutson. Last year we collaborated with the econ group on another panelized project in Vancouver (photos here) and we expect to be partners on many more projects in the future. Check their website and tweets for updates.

Stefan has been working with this group for months to finalize the Cadwork cad/cam model and manage the fabrication in Portland. The full photo collection is available on flickr, and some selected images are below.

After all the modeling Stefan generated renderings, three examples below,

Deliveries of lots of wood to the factory.

and a lot of cutting on our Hundegger lines

and some larger "sticks"

and some lots of angle cuts, here are some LVL rim boards

some LSL edge boards for floor panels

some dormer components

it has been very helpful to use the high speed printer heads to mark each piece

the shop has been very busy, with a few very large assemblies being produced by Tony and team.

and assembling all of these components into panels has kept Nate's team very busy

and optimizing the loading of the trucks has taken a lot of work and planning

and now to delivery and assembly at the site. Check back for more images and videos.

Saturday, February 11, 2012

CutMyTimber joins Passive House Northwest Group - Looking forward to the PHNW Spring Conference in Portland

We are already very well-connected to the Passive House community in British Columbia, represented by the Canadian Passive House Institute (CanPHI), and received our passive house training from Guido Wimmers of Building Evolution of (we made an earlier blog post about our training here).

We were previously members of Passive House California and need to renew membership. Next week Greg is flying to New York for a conference on Digital Fabrication of buildings and will also be meeting with the passive house team at 475, a high-performance building supply company and active members of the New York Passive House group. We are too busy building to stay up-to-date with all of these passive house groups but are enthused that the NY, CA, and PNW groups collaborated to form the American Passive House Network (we wish it was named the North American Passive House Network so people understand collaboration with Canadian groups).

Labels:

aphnetwork,

building evolution,

cadwork,

california passive house,

canphi,

Digital Fabrication,

fertigbau,

Guido Wimmers,

hundegger,

linkedin,

Passive House,

Passivhaus,

phnw,

prefab,

timber frame

Wednesday, September 21, 2011

Welcome to the Team!

Ian recently completed the Timber Framing certificate at the College of the Rockies and had the chance to learn from and work closely with Stefan on the class project (more on this impressive building in a future post). With a deep interest in efficient responsible building solutions, Ian holds a certificate in Sustainable Renovations from Fleming College, as well as an Associate Bachelors in Arts and Sciences from Langara College where he focused on Urban Planning, Sustainability, and Architecture History (check out some of his writings on the subject, here).

So far Ian has proven to be a valuable member of the team contributing in a drafting and project management capacity. He will also be responsible for maintaining this blog so check back soon for more updates!

Tuesday, September 20, 2011

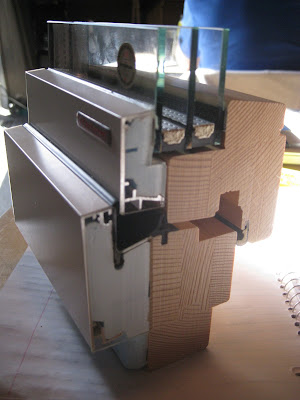

CMT Prefabricated Facade Panels

2011 has been a very busy and productive year so far, and we have lots to share with you, including our new Prefabricated Facade Panels (pictured above).

The panels are a product of a research and development project in collaboration with Anderson+Anderson Architecture and Bay Pacific Construction. We are now happy to offer them as part of our growing roster of in-house prefabricated building solutions.

Cut with our Hundegger SC-1with Dovetail mill creating a wood-on-wood connection secured using galvanized and special treated self-drilling deck screws. The result is a modern, modular, sustainable cladding solution that can be built in any dimension up to 8' wide by 28' long.

IG

The panels are a product of a research and development project in collaboration with Anderson+Anderson Architecture and Bay Pacific Construction. We are now happy to offer them as part of our growing roster of in-house prefabricated building solutions.

Cut with our Hundegger SC-1with Dovetail mill creating a wood-on-wood connection secured using galvanized and special treated self-drilling deck screws. The result is a modern, modular, sustainable cladding solution that can be built in any dimension up to 8' wide by 28' long.

Ultimately customizable, choose from a variety of species (including Oak, Redwood, and Western Red Cedar seen above), surface treatments (from rough sawn to four-sided planed), and finishes (stained, or for a natural look try LandArk Exterior Finish as pictured above.)

Taking advantage of 3D modelling technology, all customization takes place first in the virtual world then in our factory setting with no on-site adaptation required. This dramatically speeds up the process of siding a building: an entire house can be sided and finished in a few days using our Prefabricated Facade Panel system.

A 100% sustainable product, our Prefabricated Facade Panels make use of local renewable materials with low embodied energy. Our optimized 3D design and efficient CNC process yields a minimum of offcut waste.

A perfect solution for an aging building needing a facelift, or a new build trying to achieve a clean modern look. For more information on this and any of our other prefabricated building solutions, please contact us.

Check back in the next few weeks as we introduce a new member of the CutMyTimber team, and showcase a few projects we have been busy with over the past few months.

Tuesday, November 16, 2010

CutMyTimber trained in Passive House

I think we all agree that homes need to be more energy efficient. There is a lot of talk about different systems and standards. I was trained and involved in many Minergie projects in the past.

Dr. Wolfgang Feist,German Professor and founder of the Passive House Institute went a step further and developed one of the highest green building standards in the world.

CutMyTimber spent a lot of time researching and testing various standards, products and software tools. We came to the conclusion that at this point the Passive House standard is probably the most advanced and thought-out green building standard at this point.

CutMyTimber spent a lot of time researching and testing various standards, products and software tools. We came to the conclusion that at this point the Passive House standard is probably the most advanced and thought-out green building standard at this point.

Therefore it’s no surprise that there is a strong move in Passive House all over North America. We are fortunate to have many local PH experts in Vancouver. This was probably also the reason why the very first Passive House Designer/Consultant course took place in Vancouver.

I was one of the 25 professionals that took this very interesting course. We had a really good crowd mixed with engineers, architects, builders, building inspectors, green building consultants and building scientists.

What is a Passive House?

Basically a Passive House is a high performance building that uses solar (south windows) and interior heat gains (people, electronics, etc.) Please see Passipedia for more details.

Passive Houses require less than 15 kWh/(m²yr) for heating or cooling (relating to the living space).

(Graphic: PH Institute) 1. Building shape, Compactness (Area/Volume ratio)

2. Building orientation and window position/Solar exposure

3. Building shell: High performance walls, roofs and foundation.

4. Windows: Triple pane, double low e glazing windows with U-values of <0.8W/m2K

5. Airtightness: Extreme tight building envelope (0.6 ach@50Pa)

6. Thermal bridge free construction

7. Heat recovery ventilation system

Following a few slides from our course.

Compactness and orientation of a building has a huge impact of heat and cooling energy consumption. The more compact a building is the better. Ideal building orientation is North-South.

The Building shell is one of the most important elements of a Passive Building. We require highly insulated and airtight walls. Ideally free of thermal bridges or penetrations. A Passive House should have R40 or better walls and R45 or better roof (depending on location and many other factors). Malcolm explains a Passive House compatible floor to wall connection detail.

Thermal bridges that can’t be avoided need to be calculated. The calculation results have to be entered in the Passive House Software (PHPP). PHPP will consider these in the overall energy calculation.

Penetrations in the building envelope should be avoided in order to achieve an airtight building. We learned about innovative products that can be used if there is no way to avoid a penetration. Unfortunately these grummets are not available in North America yet.

We learned a lot about the newest generation of windows. High quality windows triple pane, double low e glazing windows with U-values of <0.8W/m2K are essential for a Passive Building. Innovative window manufacturers came up with insulated window frames.

Unfortunately it’s hard to get windows with PH proprieties in North America. Many companies are working on it and it looks like we will see a new generation of window on the market soon.

Because of the tight building shell a controlled air exchange is really important in a Passive House. A heat recovery ventilation system (HRV) is part of every passive house and requires proper planning.

Today’s Heat recovery units achieve efficiencies of 90% or more. Malcolm presents a few of the most efficient units currently available.

We also got exposed to a few of the currently available Passive House building Materials. Without pushing certain brands or products we had a chance to see new wind and vapor barriers, sealing tapes, ventilation ducts and nozzles.

Guido Wimmers opens the champagne at the end of the first Passive House Course in Canada. Many Thanks again to Guido, Malcolm, Andrea and Stephan for such a great course!! To my classmates: It was nice to meet you all and I hope we can pursue the Passive House move and be part of the local PH community.

I can’t wait to design or manufacture our first Passive House.

Stefan Schneider, CutMyTimber INC.

USEFUL PASSIVE HOUSE LINKS:

Stefan Schneider, CutMyTimber INC.

USEFUL PASSIVE HOUSE LINKS:

Tuesday, October 26, 2010

Timber Frame Raising in Oregon, USA

The frame we cut a few weeks ago has been successfully delivered and installed.

The building site is beautiful, in the middle of Oregon's wine country. How much nicer could it possibly be?

The raising crew was lucky and had mostly nice weather. They did an amazing job and managed to install the frame in less than 3 days.The pre-cut SIP panels got installed in 3 days as well.

The building site is beautiful, in the middle of Oregon's wine country. How much nicer could it possibly be?

The raising crew was lucky and had mostly nice weather. They did an amazing job and managed to install the frame in less than 3 days.The pre-cut SIP panels got installed in 3 days as well.

All CNC pre-cut joinery fit perfectly. The high level of details paid off and made for a stress free installation on site. Things like chamfered tenons, pre-drilled peg holes and proper labeling make a HUGE difference for the assembly crew. Read more about how we fabricated this timber frame in an earlier blog.

Nice and tight!!! Traditional tapered shoulder girt to post connection with hidden spline and position tenon.

Thanks again to my team, the raising crew, and everybody involved. You all did a wonderful job!!

Congratulations to the new owner of the house. I am sure this timber frame will last for generations making it a pleasant healthy home for you and your guest.

Sunday, October 17, 2010

CutMyTimber visiting IDSWest show October 14-17, 2010

Last Friday evening Guido Holdener from Equilibrium Consulting and myself decided to leave the traditional building world for a few hours. We visited to Interior Design show IDSwest.

We very much enjoyed extending our horizon and look at some of the finest design and artwork BC has to offer.It was a pleasure to see some very innovative and creative interior designers, artists, and architects.

Laminated, plywood-style exterior garden bench. Very cool!!

The main focus of our visit was the showcase home from our friends at Preform Construction in Surrey.

On display was their second iteration of their very successful pre-designed modular home. The home on display was a 1000sf house.

The modular concept glanced with top notch build and finishing quality, smart design, and very spacious feel inside. I absolutely loved the modern interior with hight ceilings, bright withe walls, lots of glass, and sharp edges. And of course Preform followed their strategy of highly energy efficient and green homes.

Congratulations to Ryan Spong at Preform Construction and his team as well as architect Tony Robins at AA Robins Architect fort a great design and concept.

Very well done! Design and realization. Hopefully this high level showcase home will get more future home owners excited for smart homes.

We very much enjoyed extending our horizon and look at some of the finest design and artwork BC has to offer.It was a pleasure to see some very innovative and creative interior designers, artists, and architects.

Laminated, plywood-style exterior garden bench. Very cool!!

The main focus of our visit was the showcase home from our friends at Preform Construction in Surrey.

On display was their second iteration of their very successful pre-designed modular home. The home on display was a 1000sf house.

The modular concept glanced with top notch build and finishing quality, smart design, and very spacious feel inside. I absolutely loved the modern interior with hight ceilings, bright withe walls, lots of glass, and sharp edges. And of course Preform followed their strategy of highly energy efficient and green homes.

Congratulations to Ryan Spong at Preform Construction and his team as well as architect Tony Robins at AA Robins Architect fort a great design and concept.

Very well done! Design and realization. Hopefully this high level showcase home will get more future home owners excited for smart homes.

Subscribe to:

Posts (Atom)