I think we all agree that homes need to be more energy efficient. There is a lot of talk about different systems and standards. I was trained and involved in many Minergie projects in the past. Dr. Wolfgang Feist,German Professor and founder of the Passive House Institute went a step further and developed one of the highest green building standards in the world.

CutMyTimber spent a lot of time researching and testing various standards, products and software tools. We came to the conclusion that at this point the Passive House standard is probably the most advanced and thought-out green building standard at this point. Therefore it’s no surprise that there is a strong move in Passive House all over North America. We are fortunate to have many local PH experts in Vancouver. This was probably also the reason why the very first Passive House Designer/Consultant course took place in Vancouver.

I was one of the 25 professionals that took this very interesting course. We had a really good crowd mixed with engineers, architects, builders, building inspectors, green building consultants and building scientists.

What is a Passive House?

Basically a Passive House is a high performance building that uses solar (south windows) and interior heat gains (people, electronics, etc.) Please see Passipedia for more details. Passive Houses require less than 15 kWh/(m²yr) for heating or cooling (relating to the living space). (Graphic: PH Institute)

In a nutshell following points are essential for Passive House design:

1. Building shape, Compactness (Area/Volume ratio)

2. Building orientation and window position/Solar exposure

3. Building shell: High performance walls, roofs and foundation.

4. Windows: Triple pane, double low e glazing windows with U-values of <0.8W/m2K

5. Airtightness: Extreme tight building envelope (0.6 ach@50Pa)

6. Thermal bridge free construction

7. Heat recovery ventilation system

Following a few slides from our course.

First morning: Malcolm Isaacs and Dr. Guido Wimmers start the course and introduce the other instructors Dr. Andrea Frisque and Stefan Lotz. I felt very fortunate to have such a knowledgeable and passionate Passive House training team. Our instructors didn’t just talk about Passive House. All of them are very actively involved with the PH Institute in Germany, they are involved in current Passive House projects and clearly they knew their stuff and truly believe in Passive Buildings. Thanks again for such a great course.

Compactness and orientation of a building has a huge impact of heat and cooling energy consumption. The more compact a building is the better. Ideal building orientation is North-South.

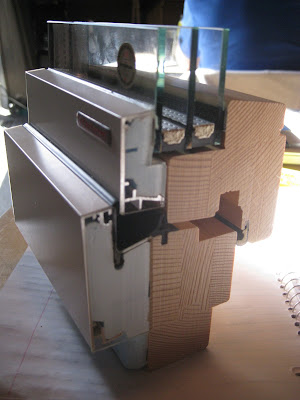

The Building shell is one of the most important elements of a Passive Building. We require highly insulated and airtight walls. Ideally free of thermal bridges or penetrations. A Passive House should have R40 or better walls and R45 or better roof (depending on location and many other factors). Malcolm explains a Passive House compatible floor to wall connection detail.

Thermal bridges that can’t be avoided need to be calculated. The calculation results have to be entered in the Passive House Software (PHPP). PHPP will consider these in the overall energy calculation.

Penetrations in the building envelope should be avoided in order to achieve an airtight building. We learned about innovative products that can be used if there is no way to avoid a penetration. Unfortunately these grummets are not available in North America yet.

We learned a lot about the newest generation of windows. High quality windows triple pane, double low e glazing windows with U-values of <0.8W/m2K are essential for a Passive Building. Innovative window manufacturers came up with insulated window frames.

Unfortunately it’s hard to get windows with PH proprieties in North America. Many companies are working on it and it looks like we will see a new generation of window on the market soon.

Because of the tight building shell a controlled air exchange is really important in a Passive House. A heat recovery ventilation system (HRV) is part of every passive house and requires proper planning.

Today’s Heat recovery units achieve efficiencies of 90% or more. Malcolm presents a few of the most efficient units currently available.

We also got exposed to a few of the currently available Passive House building Materials. Without pushing certain brands or products we had a chance to see new wind and vapor barriers, sealing tapes, ventilation ducts and nozzles.

Guido Wimmers opens the champagne at the end of the first Passive House Course in Canada. Many Thanks again to Guido, Malcolm, Andrea and Stephan for such a great course!! To my classmates: It was nice to meet you all and I hope we can pursue the Passive House move and be part of the local PH community.

I can’t wait to design or manufacture our first Passive House.

Stefan Schneider, CutMyTimber INC.

USEFUL PASSIVE HOUSE LINKS: