Last week we completed fabrication of a panelized passive house in Portland. Trucks continue to be loaded and assembly will begin next week. We are really excited about this project and how it will demonstrate advanced digital fabrication and high-performance.

We have great partners on this project and are very excited to be working with Guido Wimmers PhD, our passive house trainer, staff member of the Canadian Passive House Institute, advisor to the City of Vancouver on the passive house design toolkits, and owner of building evolution.

We are working with an incredible client, Shirra, who is great to work with and who is very interested in demonstrating the benefits of passive house on her own residence. We are also excited to be working with our builder friends at the Econ Group, Marcel Studer and Michael Dutson. Last year we collaborated with the econ group on another panelized project in Vancouver (photos here) and we expect to be partners on many more projects in the future. Check their website and tweets for updates.

Stefan has been working with this group for months to finalize the Cadwork cad/cam model and manage the fabrication in Portland. The full photo collection is available on flickr, and some selected images are below.

After all the modeling Stefan generated renderings, three examples below,

Deliveries of lots of wood to the factory.

and a lot of cutting on our Hundegger lines

and some larger "sticks"

and some lots of angle cuts, here are some LVL rim boards

some LSL edge boards for floor panels

some dormer components

it has been very helpful to use the high speed printer heads to mark each piece

the shop has been very busy, with a few very large assemblies being produced by Tony and team.

and assembling all of these components into panels has kept Nate's team very busy

and optimizing the loading of the trucks has taken a lot of work and planning

and now to delivery and assembly at the site. Check back for more images and videos.

Showing posts with label prefab. Show all posts

Showing posts with label prefab. Show all posts

Saturday, February 11, 2012

CutMyTimber joins Passive House Northwest Group - Looking forward to the PHNW Spring Conference in Portland

We are already very well-connected to the Passive House community in British Columbia, represented by the Canadian Passive House Institute (CanPHI), and received our passive house training from Guido Wimmers of Building Evolution of (we made an earlier blog post about our training here).

We were previously members of Passive House California and need to renew membership. Next week Greg is flying to New York for a conference on Digital Fabrication of buildings and will also be meeting with the passive house team at 475, a high-performance building supply company and active members of the New York Passive House group. We are too busy building to stay up-to-date with all of these passive house groups but are enthused that the NY, CA, and PNW groups collaborated to form the American Passive House Network (we wish it was named the North American Passive House Network so people understand collaboration with Canadian groups).

Labels:

aphnetwork,

building evolution,

cadwork,

california passive house,

canphi,

Digital Fabrication,

fertigbau,

Guido Wimmers,

hundegger,

linkedin,

Passive House,

Passivhaus,

phnw,

prefab,

timber frame

Friday, October 8, 2010

Timber frame fabrication in Cascadia

Last week was an intense series of long days during which we cut 148 timbers into a net 6,200 board feet of Oregon Douglas fir in 28 hours of machine time on a 5-axis Hundegger K2 joinery machine.

Oregon has some of the best Douglas fir on the planet and it is a great pleasure to work with it and combine advanced design technologies with traditional craftsmanship. Working with a great team only adds to the experience.

The K2 ran continuously each work day while we also completed all the required craft work.

The brand new Makita KB-312 planer is amazing and a lot of fun. We ran thru 2 sets of knives to ensure an absolutely clean surface.

Old Bavarian craftsman-ship never gets rusty. " Gelernt ist gelernt !!!"

Oregon has some of the best Douglas fir on the planet and it is a great pleasure to work with it and combine advanced design technologies with traditional craftsmanship. Working with a great team only adds to the experience.

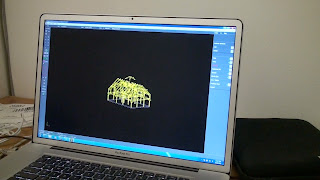

Beautifully timbers, Technology and craftsmanship is the recipe for some great timber frames. The process starts in the office with very detailed and throughout 3D design:

We use the 3D computer model to select timbers. We try to use the nicest timbers for highly visible faces. The less nice stuff goes towards the non visible outside. It's absolutely critical to have perfectly straight parts for the exterior wall columns and gable rafters. Again the mobile netbook computer makes it easy to have complete control while sorting timbers.

Some of the more involved parts. The more complex the parts are the more we love the K2 joinery machine!!

Hip Rafter and Roof-Header with dovetail connection.

Finished dormer posts with 5ft lenght cut to make the post narrower on top. Seat-cut and mortise for dormer rafter and housing for eave plate.

The K2 ran continuously each work day while we also completed all the required craft work.

The brand new Makita KB-312 planer is amazing and a lot of fun. We ran thru 2 sets of knives to ensure an absolutely clean surface.

Old Bavarian craftsman-ship never gets rusty. " Gelernt ist gelernt !!!"

We test-fit every part to ensure a tight fit and no hand work on construction site.

Girt to post connection with Maple hardwood spline and positioning tenon. We test fit prior to final planing and sanding to ensure parts don't have to be handled once they are clean and sanded.

We use cutting edge CNC technology to produce traditional timber framing connections such as dovetails, spline and tapered shoulders with mortise and tenons.

We chamfer all tenons to ensure quick and hassle free installation. A little touch that makes a huge difference for the install crew!!

And of course proper labeling !! Certain parts have to be installed in a specific direction.

4x8" knee braces:

We used a laser cut steel template to trace our braces.

We used Landark to finish the wood. The smell of beeswax and citrus is great. Here is a photo of some great timbers and a team member applying the finish.

The Douglas fir was absolutely beautiful and a pleasure to work with.

Last but not least: Proper edge protection and wrapping for shipping. Edges are really fragile and need to be protected !!

Check out pictures of the installed Timber Frame.

Labels:

cam,

cascadia,

cnc,

douglas fir,

hundegger,

K2,

landark,

prefab,

timber frame

Subscribe to:

Posts (Atom)